-

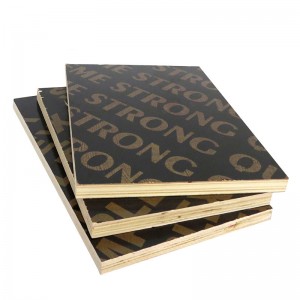

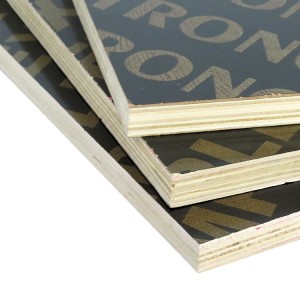

Concrete Formwork Wood Plywood

The film faced plywood has high corrosion resistance and moisture resistance, easy to combine with other materials, easy to clean and cut.

The color of the film faced plywood is bright,clean, smooth, and the appearance is black (red, brown or as required), and the logo can be printed according to requirements. -

High Level Anti-Slip Film Faced Plywood

The film of black brazil film faced plywood for construction is mainly imported from Brazil. The density of this plywood is mainly around 500 to 700 kg/cbm. The surface of plywood is smooth, the use effect is good. The raw materials used are of uniform thickness and good flexibility. This plywood is durable, corrosion-resistant and reusable.

-

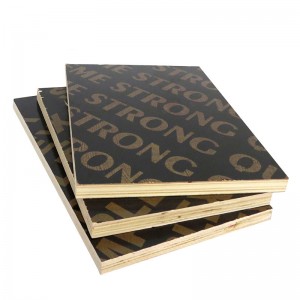

High Quality Black Film Faced Plywood For Construction

The production operation adopts cold/hot pressing technology to strictly control the pressing temperature, pressure intensity and pressing time to ensure that the plywood has good compressive strength. After 28 procedures, two times of pressing, five times of inspection and high-precision size can be packaged.

-

Black Film Color Veneer Board Film Faced Plywood For Concrete And Construction

This high quality black film faced plywood for construction is can be one time hot pressed,or two times hot pressed. It mainly used for concrete pouring construction, houses, bridges, schools, hospitals,water conservancy projects and other projects. The surface of High Quality Black Film Faced Plywood is very smooth and bright, so it shows very good demoulding performance when pouring concrete.

-

Black Brazil Film Faced Plywood For Construction

We produce anti-slip film faced plywood, which has the advantage of anti-slip compared with ordinary plywood.On its surface,there are special films,made with phenolic or melamine glue,and there is waterproof paint on its edge.So it is better in waterproof advantages and perform longer in wet conditions. It can be recycled to use many times.

-

Super Smooth Film Faced Plywood

Brown film faced plywood is an exterior plywood used in building and construction projects. It has brown or black film coating on made with phenolicor melamine glue, it has better brightness and flatness. Brown Film Faced Plywood also has higher density, so it is stronger and better waterproof application. The brown film can give the plywood higher resistance to moisture, abrasion, chemical degradation and fungal attack compared to ordinary plywood.

-

Melamine Faced Concrete Formwork Plywood

The film faced plywood has high corrosion resistance and moisture resistance, easy to combine with other materials, easy to clean and cut.

The color of the film faced plywood is bright,clean, smooth, and the appearance is black (red, brown or as required), and the logo can be printed according to requirements.

-

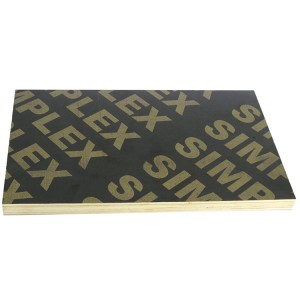

Film Faced Plywood Black Board

The standard size specifications of this plywood is divided into: 1220mm*2440mm and 1830mm*915mm, and the thickness is generally between 11-21mm.

The surface of this plywood is smooth and flat, and it is easy to demould during use, which makes the surface of the concrete smooth and convenient for workers to operate. Select high-quality pine wood and eucalyptus wood as raw materials, which have small lump and good toughness.

-

15mm Formwork Phenolic Brown Film Faced Plywood

The Super Smooth Film Faced Plywood has a smooth surface, is easy to demould, and has a good use effect. It is easy to clean with water or steam, which helps to improve the efficiency of engineering construction.

After 28 procedures, two times of pressing, five times of inspection and high-precision size can be packaged.

-

New Architectural Membrane Plywood

The secondary molding of film-coated plywood has good gloss, hardness, high strength, and smooth surface. Secondly, it has good water resistance and waterproof performance, so the formwork is not easy to be deformed and out of shape, with long service life and high turnover. It is the main product of Monster Wood , a construction plywood manufacturer. Once again, it has strong anti-corrosion performance, only a few strong acids and strong alkalis can damage it, and generally it can resist.

The color of the film faced plywood is bright,clean, smooth, and the appearance is black (red, brown or as required), and the logo can be printed according to requirements.

-

18mm Film Faced Plywood Film Faced Plywood Standard

18mm film faced plywood standard is the most common specification for import and export. 18mm film faced plywood has good durability, is not easy to deform, does not warp, and it can be reused up to 15-20 times, which is environmentally friendly and the price is affordable. Specifications are 4*8;4*7;3*7;4*6;3*6, other specifications can also be customized.

-

Wooden Planks For External Use Of Buildings

Our film faced plywood the film faced plywood selects high-quality pine & eucalyptus as raw materials; High-quality and sufficient glue is used, and equipped with professionals to adjust the glue; A new type of plywood glue cooking machine is used to ensure uniform glue brushing and improve product quality.