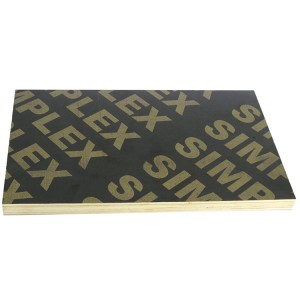

Wooden Planks For External Use Of Buildings

Product Description

Laminating is a physical process, a layer of film and a layer of aluminum plate after high temperature and high pressure pressing. Film thickness is generally between 0.1 and 0.3 mm.

The visual effect of the thick plate is more broad, but it is not the thicker the better, more than 0.6 mm is enough, the normal thickness of the film board is about 0.7 mm. The easiest way to determine thickness is to swing it around and see if it's tough.

Easy construction: one of the advantages of laminating board is convenient installation, easy construction, greatly shorten the construction period, reduce the construction cost.

Product Advantages

1. The quality of our board plywood is stable, the initial adhesion is ≧6N, and the tensile resistance is good.

2. The use performance is high, the wooden plywood is not deformed or warped, and can be reused many times.

3. The thickness of the board is uniform and the special glue is used. Ensure that the core board material is grade A, and thickness of the product meet to requirements.

4. The plywood does not crack, with strong elastic modulus, water resistance and corrosion resistance.

5. Customized size are available. Strong and rigid/Easy to clean and cut/Good chemical resistance.

Guaranteed Quality

1. Certification: CE, FSC, ISO, etc.

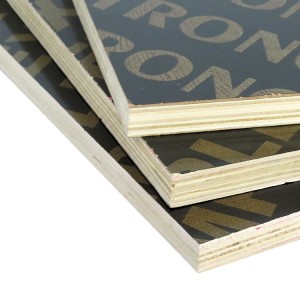

2. It is made of materials with a thickness of 1.0-2.2mm, which is 30%-50% more durable than the plywood on the market.

3. The core board is made of environmentally friendly materials, uniform material, and the plywood does not bonding gap or warpage.

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Brand Name | Xinhang | Core | pine, eucalyptus or requested by clients |

| Model Number | Film Faced Plywood | Face/Back | black(can print log) |

| Grade/Certificate | Glue | MR, melamine, WBP, phenolic | |

| Size | 1830*915mm/1220*2440mm | Moisture content | 5%-14% |

| Thickness | 11.5mm~21mm or as required | Density | 600-690 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Thickness Tolerance | +/-0.3mm | MOQ | 1*20GP. Less is acceptable |

| Usage | Outdoor, construction, bridge, etc. | Payment Terms | T/T, L/C |

| Delivery Time | Within 20 days after order confirmed |

FAQ

Q: What are your advantages?

A: 1) Our factories have more than 20 years experiences of producing film faced plywood, laminates, shuttering plywood,melamine plywood,particle board,wood veneer,MDF board,etc.

2) Our products with high-quality raw materials and quality assurance, we are factory-directly sale.

3) We can produce 20000 CBM per month, so your order will be delivered in a short time.

Q: Could you print the company name and logo on the plywood or packages?

A: Yes, we can print your own logo on plywood and packages.

Q: Why we choose Film Faced Plywood?

A: Film Faced Plywood is better than iron mould and can satisfy the requirements of constructing mould, the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing.

Q: What is the lowest priced film faced plywood?

A: Finger joint core plywood is cheapest in price. Its core is made from recycled plywood so it has low price. Finger joint core plywood can only be used two times in formwork. The difference is that our products are made of high-quality eucalyptus/pine cores, which can increase the reused times by more than 10 times.

Q: Why choose eucalyptus/pine for the material?

A: Eucalyptus wood is denser, harder, and flexible. Pine wood has good stability and ability to withstand lateral pressure.