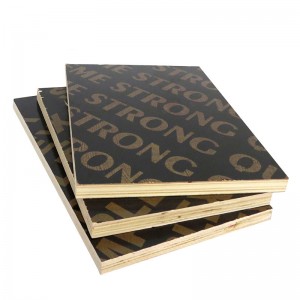

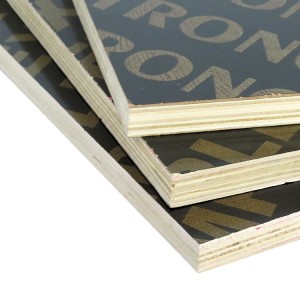

Melamine Faced Concrete Formwork Plywood

Product Description

Our film faced plywood has good durability, is not easy to deform, does not warp, and it can be reused up to 15-20 times, which is environmentally friendly and the price is affordable.

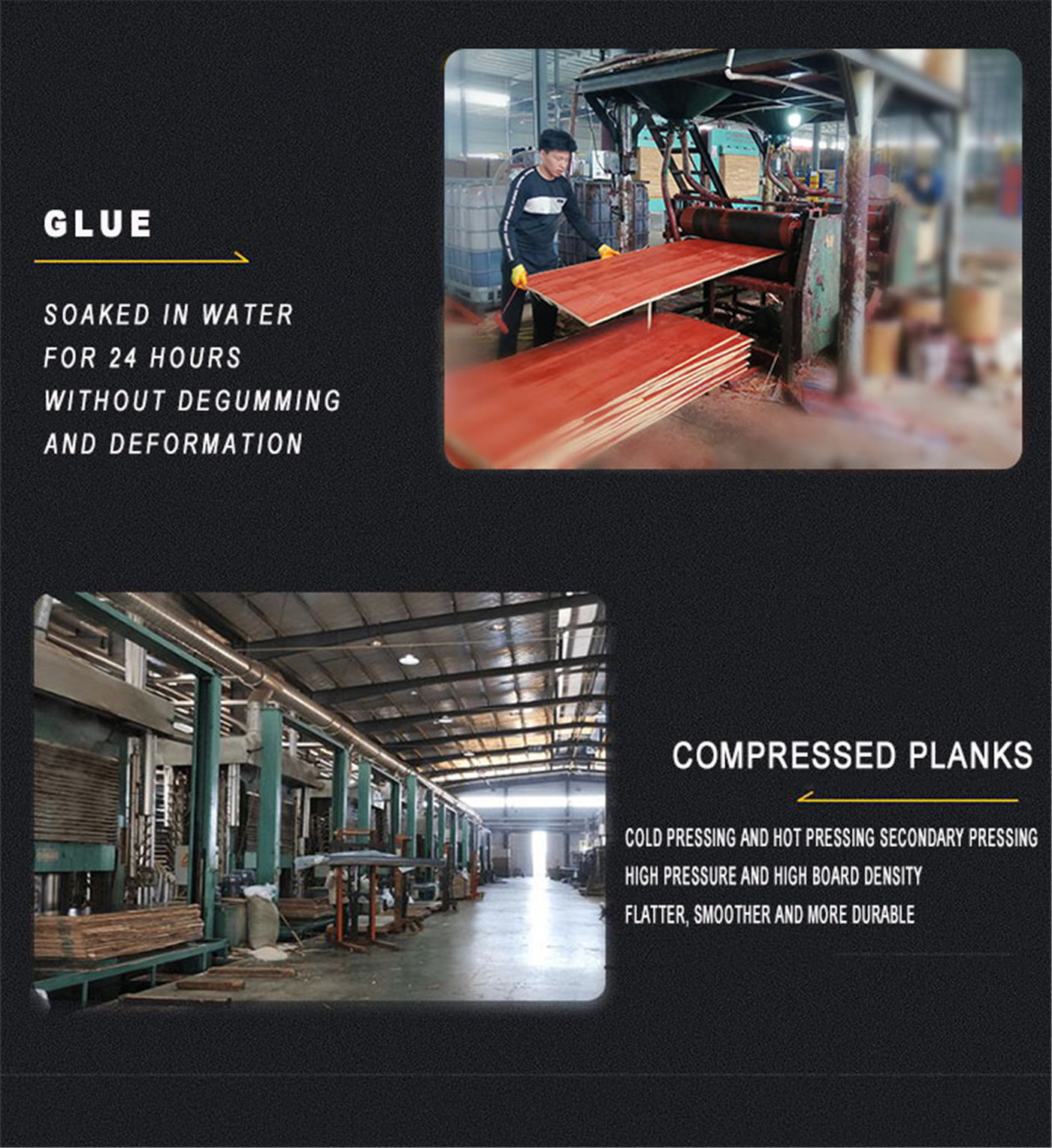

The film faced plywood selects high-quality pine & eucalyptus as raw materials; High-quality and sufficient glue is used, and equipped with professionals to adjust the glue; A new type of plywood glue cooking machine is used to ensure uniform glue brushing and improve product quality.

During the production process, employees are required to arrange boards reasonably to avoid unscientific matching of double boards, stacking of core boards, and excessive seams between plates.

The production operation adopts cold/hot pressing technology, and strictly controls the pressing temperature, pressure intensity, and pressing time to ensure a good compressive strength of the plates.

The products have undergone a number of strict quality inspection procedures, arrange shipment after packing.

The Advantages Of Our Product

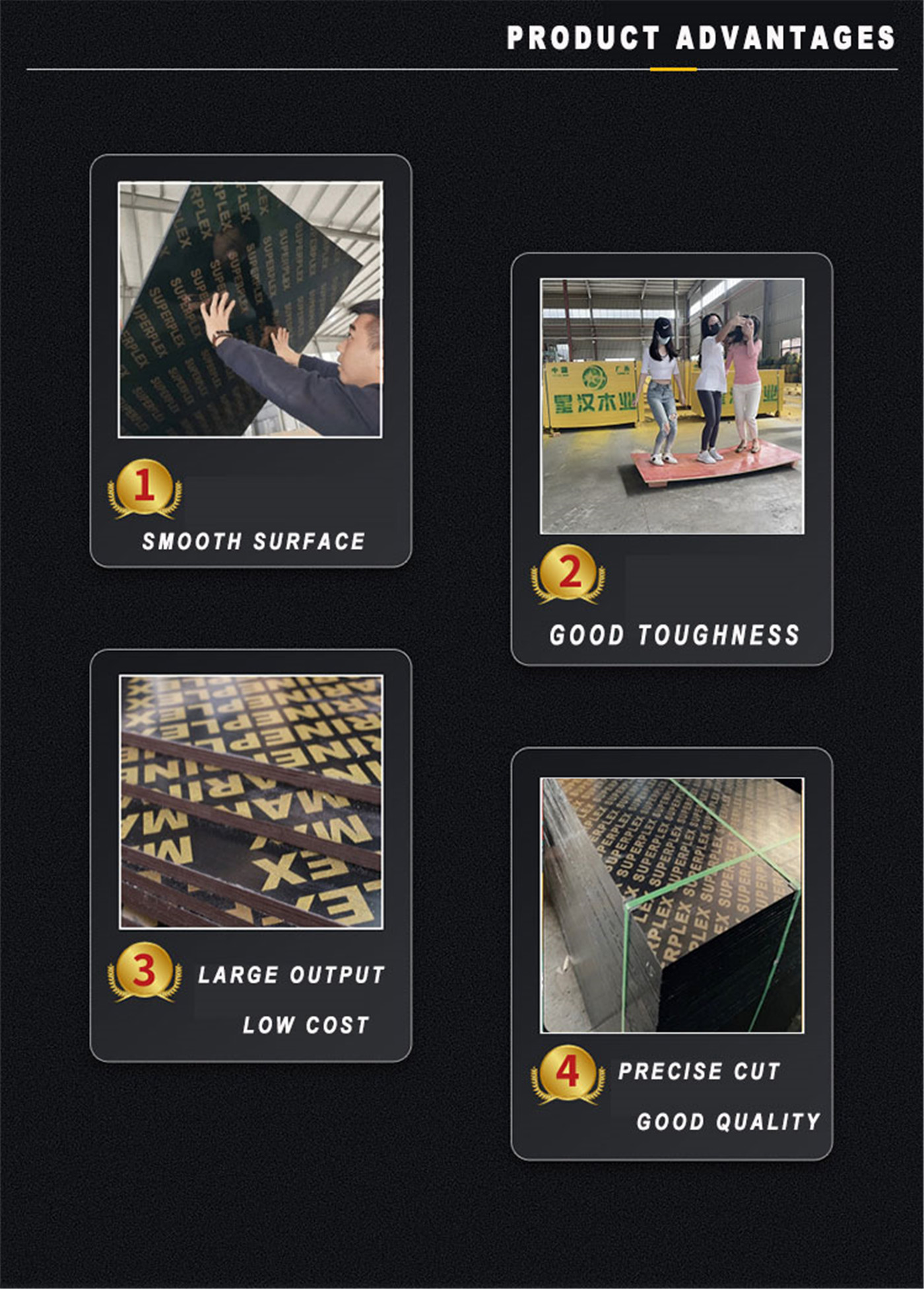

1. The quality of our board plywood is stable, the initial adhesion is ≧6N, and the tensile resistance is good.

2. The use performance is high, the wooden plywood is not deformed or warped, and can be reused many times.

3. The thickness of the board is uniform and the special glue is used. Ensure that the core board material is grade A, and thickness of the product meet to requirements.

4. The plywood does not crack, with strong elastic modulus, water resistance and corrosion resistance.

5. Customized size are available. Strong and rigid/Easy to clean and cut/Good chemical resistance.

Guaranteed Quality

1.Certification: CE, FSC, ISO, etc.

2. It is made of materials with a thickness of 1.0-2.2mm, which is 30%-50% more durable than the plywood on the market.

3. The core board is made of environmentally friendly materials, uniform material, and the plywood does not bonding gap or warpage.

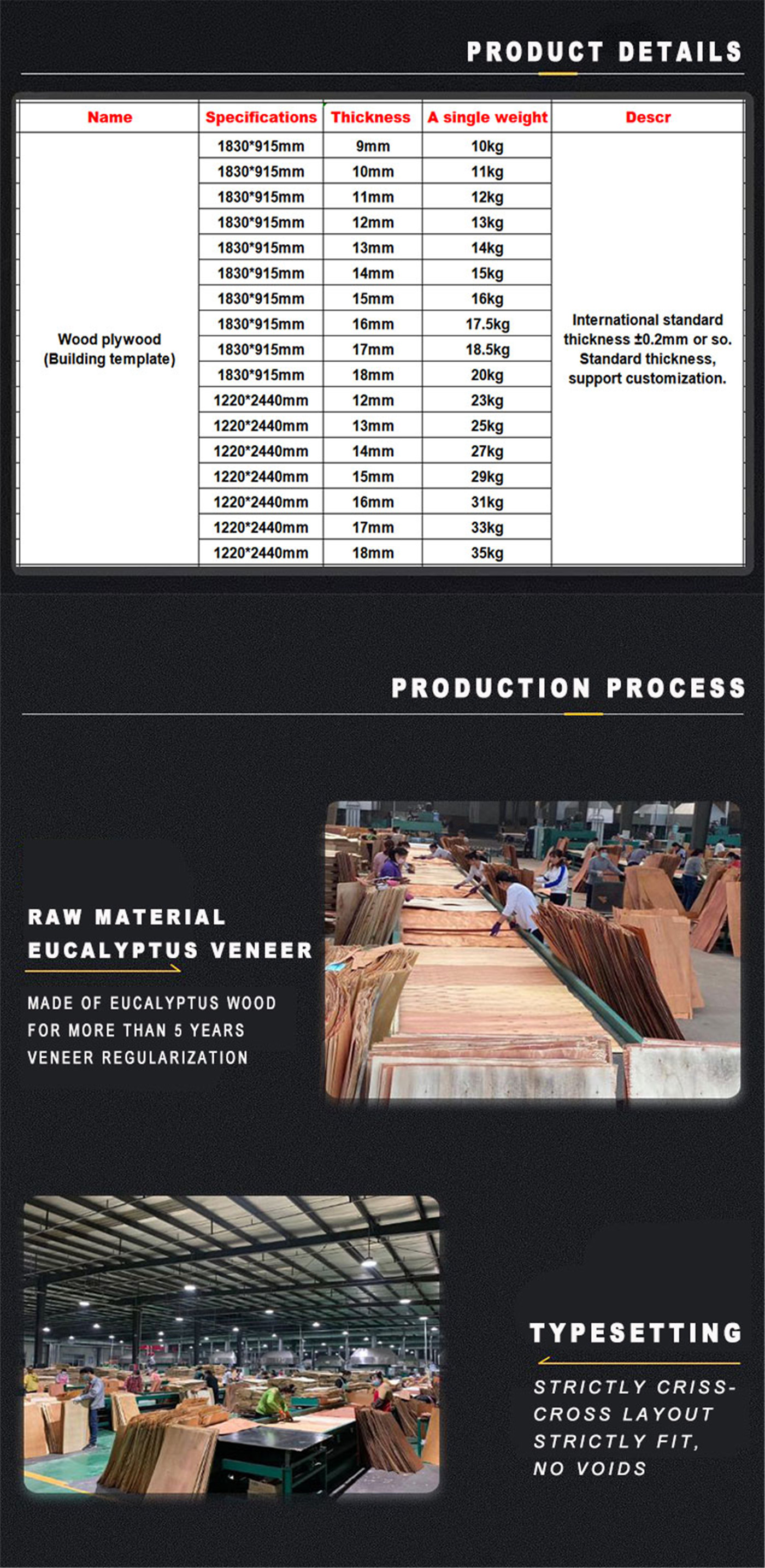

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Brand Name | Xinhang | Core | pine, eucalyptus or requested by clients |

| Model Number | MELAMINE FACED CONCRETE FORMWORK PLYWOOD | Face/Back | black(can print log) |

| Grade/Certificate | Glue | MR, melamine, WBP, phenolic | |

| Size | 1830*915mm/1220*2440mm | Moisture content | 5%-14% |

| Thickness | 11.5mm~21mm or as required | Density | 600-690 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Thickness Tolerance | +/-0.3mm | MOQ | 1*20GP. Less is acceptable |

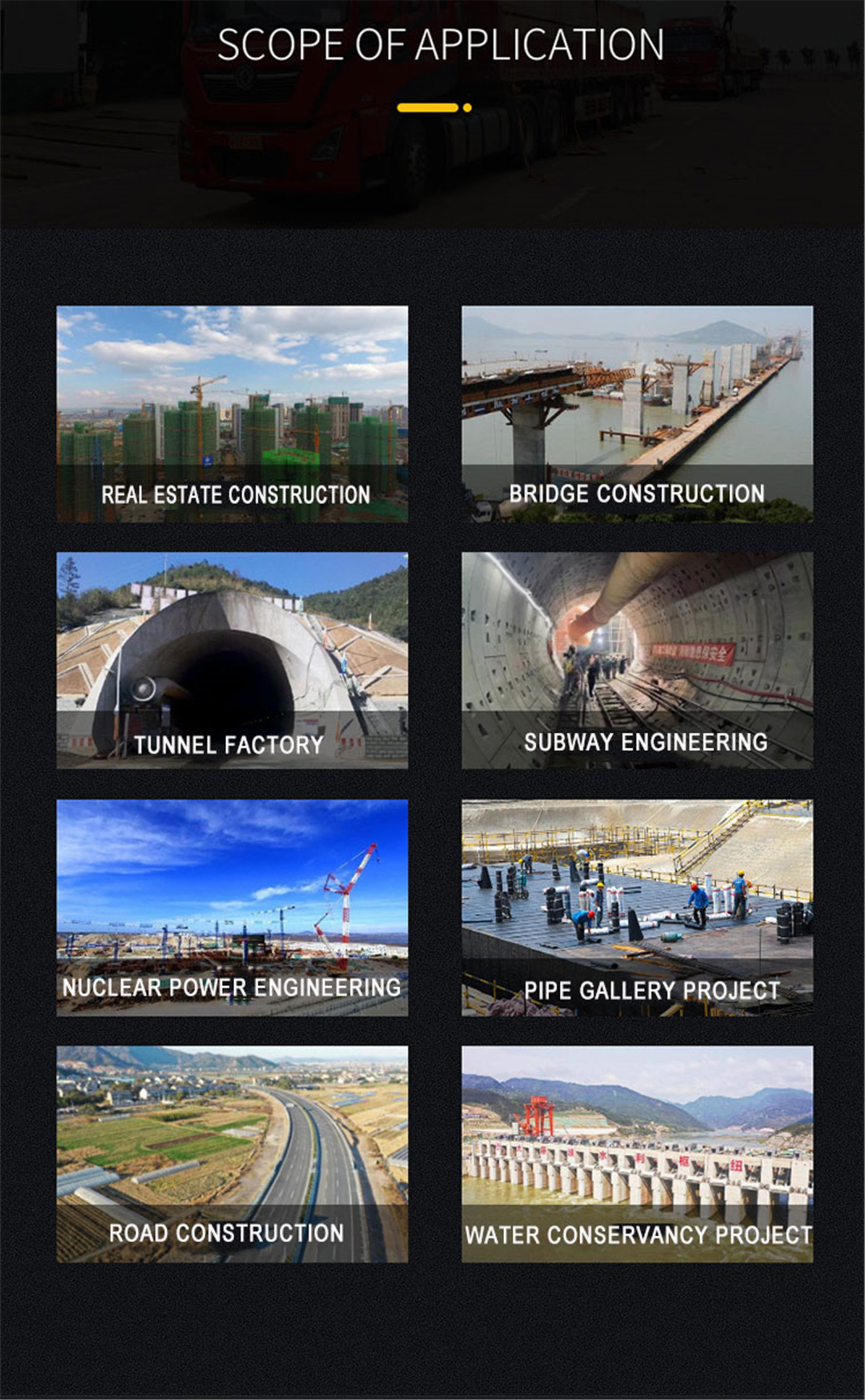

| Usage | Outdoor, construction, bridge, etc. | Payment Terms | T/T, L/C |

| Delivery Time | Within 20 days after order confirmed |