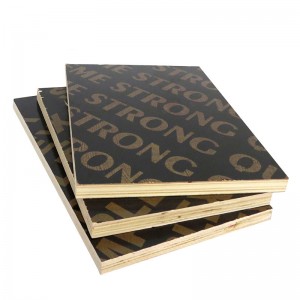

Fresh Water Formwork Film Faced Plywood

Product Description

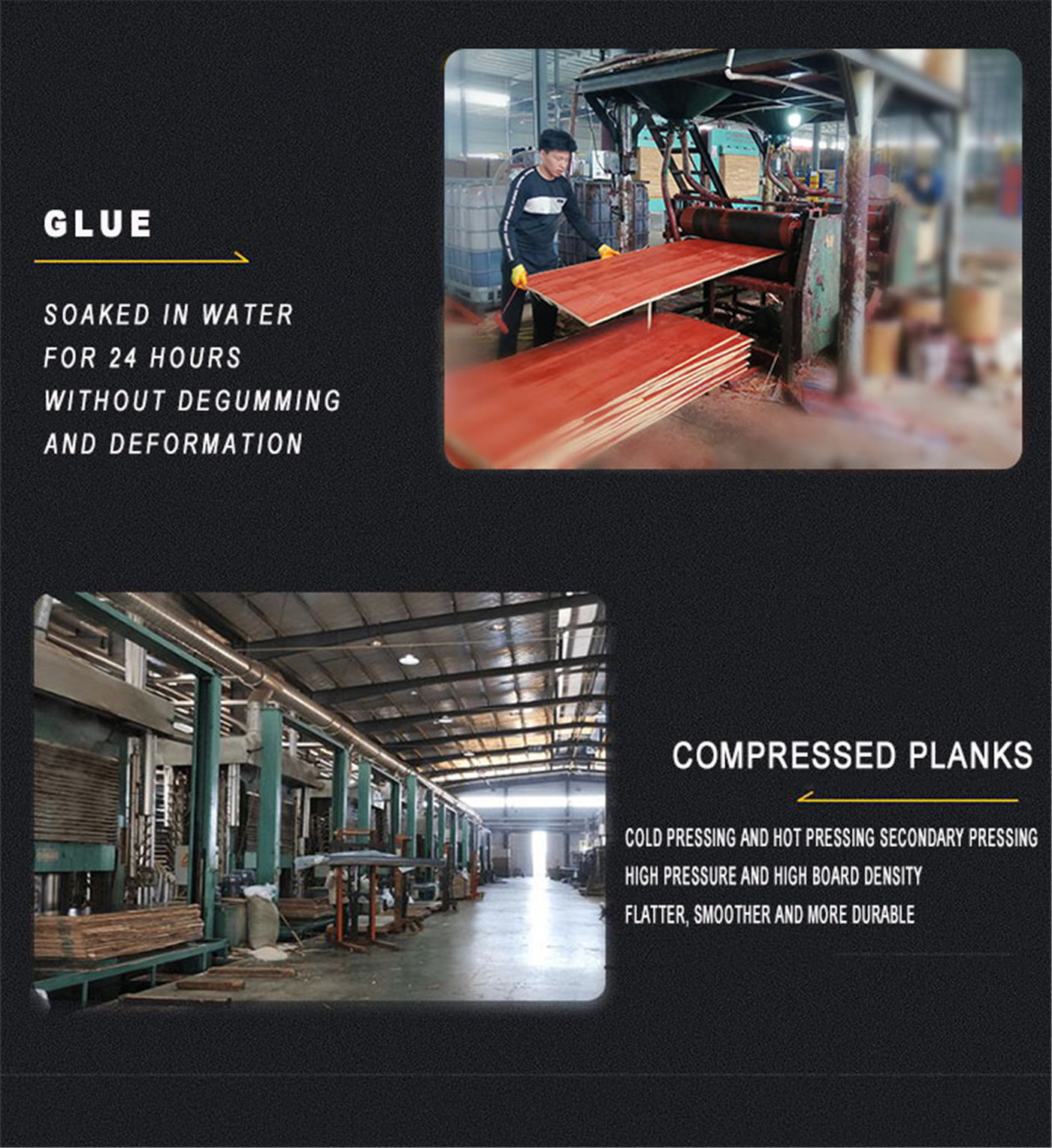

The core layer (or certain layers) consists of materials other than veneer or solid wood, and each side of the core layer has at least two layers of interlacing veneer slabs glued together.A special plywood with high water resistance is made by hot pressing a surface board impregnated with phenolic resin adhesive and a core board coated with phenolic resin adhesive.

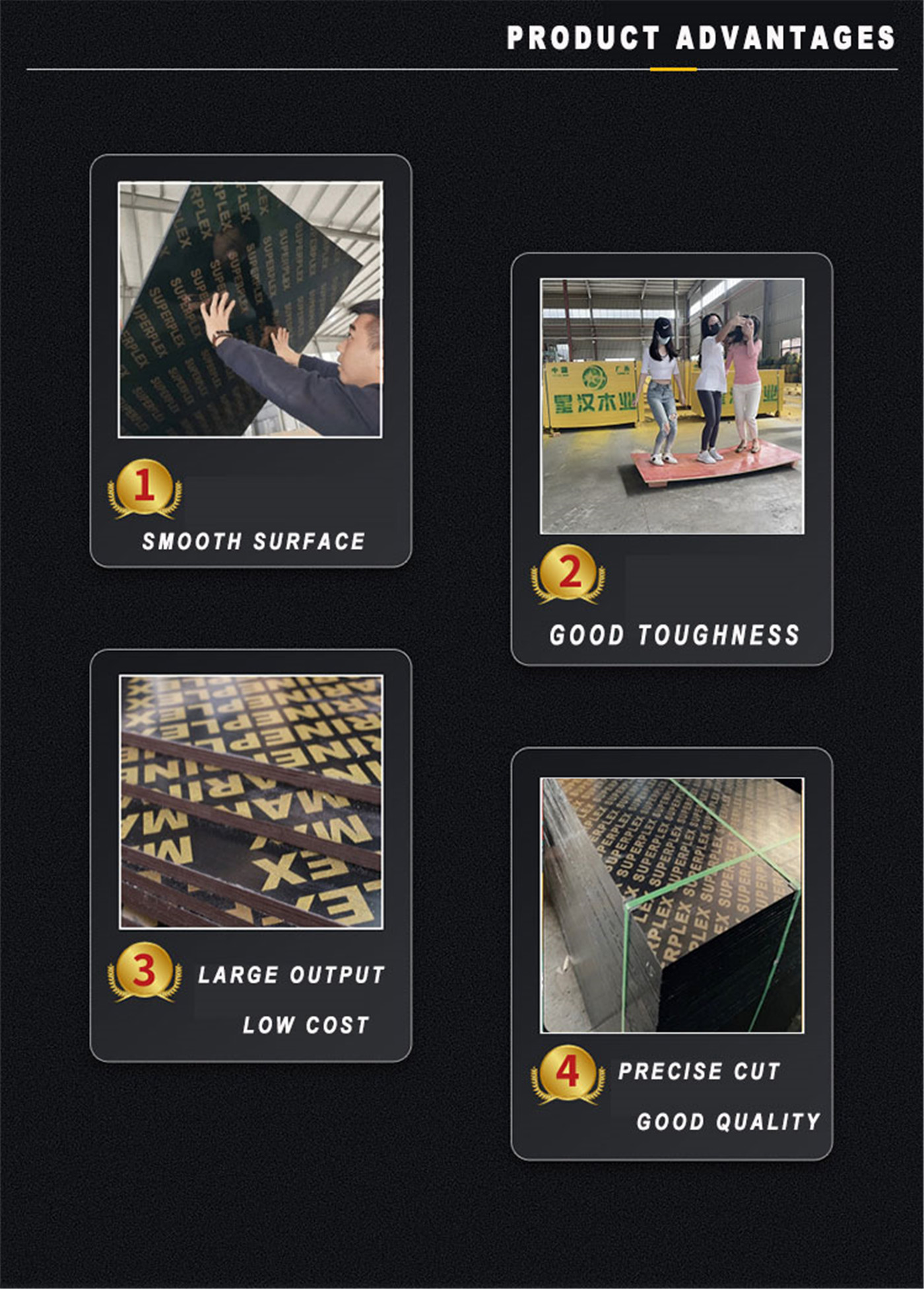

The Advantages Of Our Product

1. High-quality pine-pressed wood full-core first-class core board is used, and there is no gap between the blank boards after sawing;

2. The surface of the template is glued with phenolic resin glue with strong waterproof performance, and the core board adopts three ammonia glue (single layer glue can reach 0.45KG), using layer-by-layer glue;

3.First cold-pressed and then hot-pressed, pressed twice, the building formwork is glued, and the structure is stable.

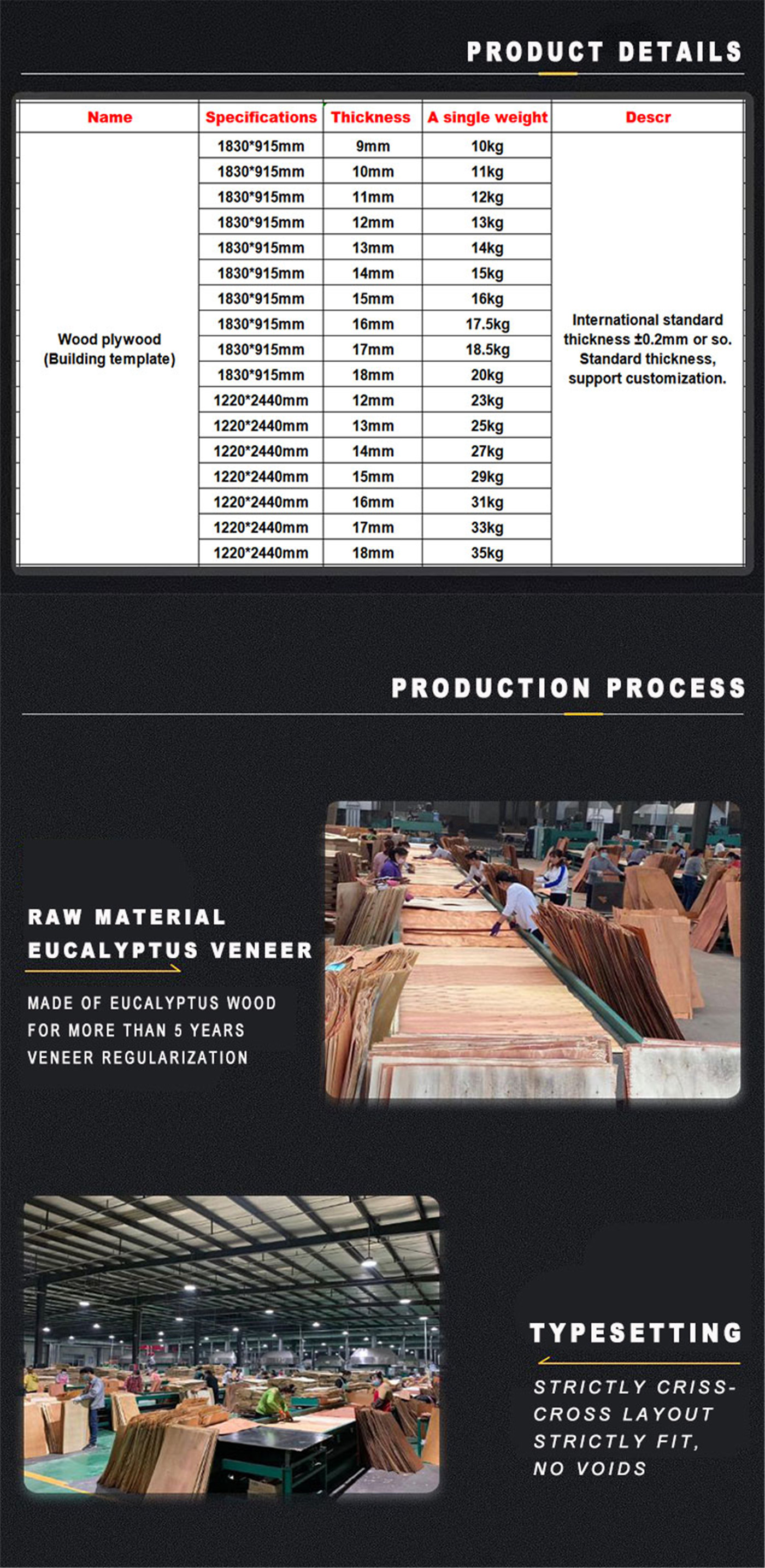

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Brand Name | Xinhang | Core | pine, eucalyptus or requested by clients |

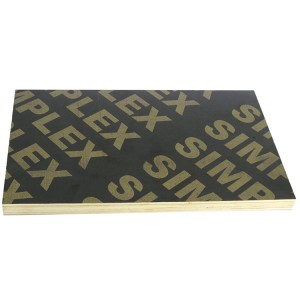

| Model Number | FRESH WATER FORMWORK FILM FACED PLYWOOD | Face/Back | black(can print log) |

| Grade/Certificate | Glue | MR, melamine, WBP, phenolic | |

| Size | 1830*915mm/1220*2440mm | Moisture content | 5%-14% |

| Thickness | 11.5mm~21mm or as required | Density | 600-690 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Thickness Tolerance | +/-0.3mm | MOQ | 1*20GP. Less is acceptable |

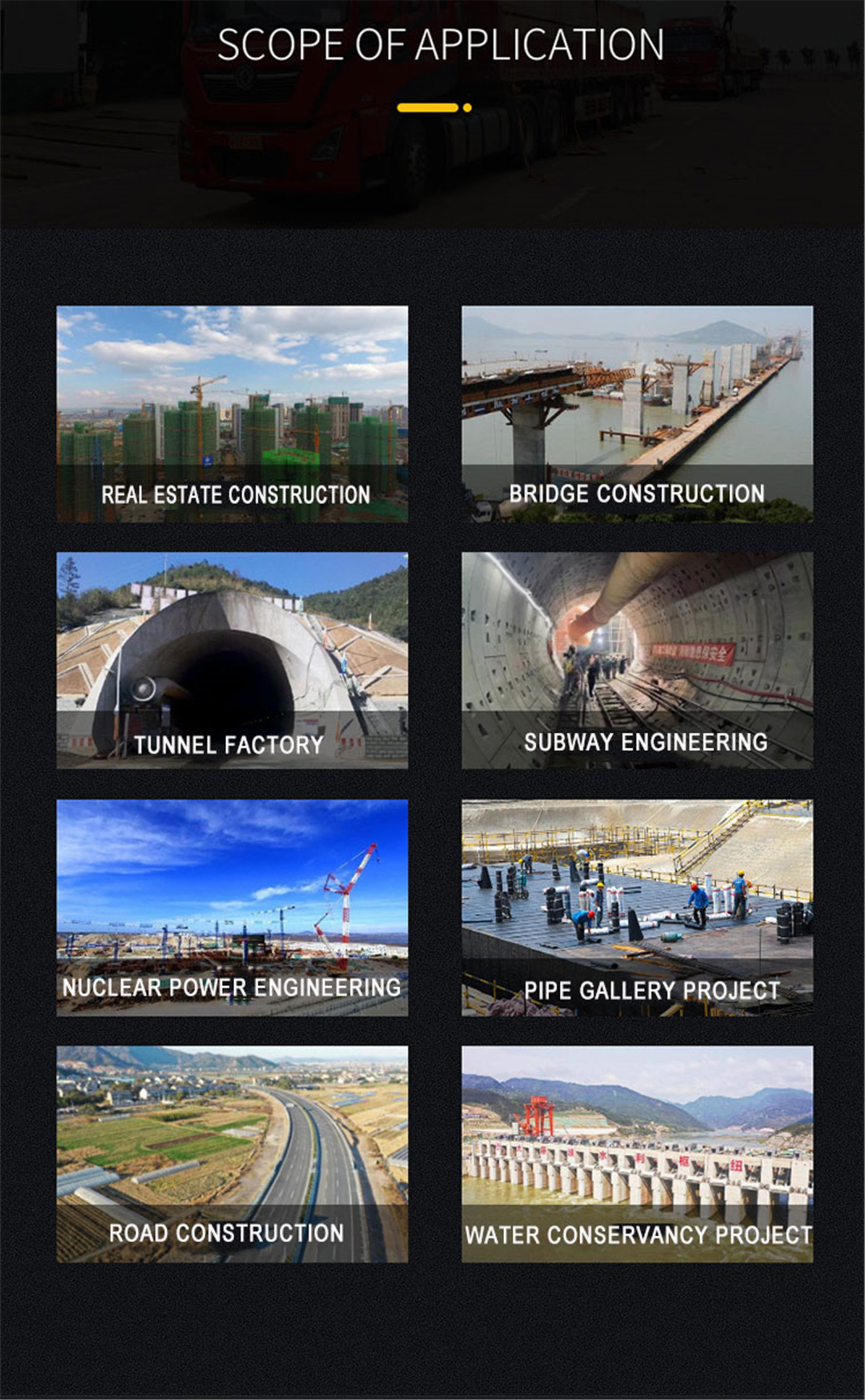

| Usage | Outdoor, construction, bridge, etc. | Payment Terms | T/T, L/C |

| Delivery Time | Within 20 days after order confirmed |