Concrete Formwork Wood Plywood

Product Description

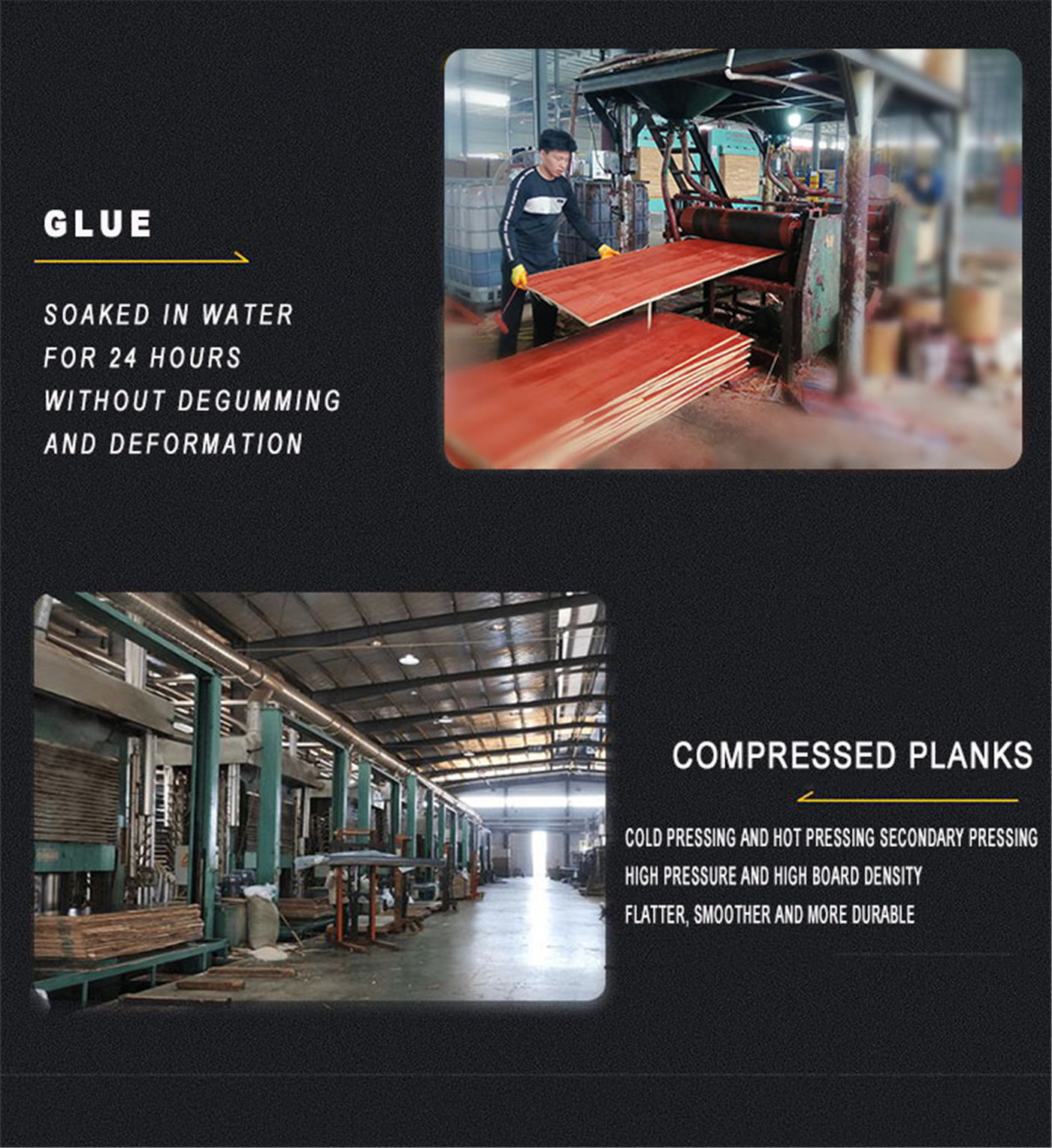

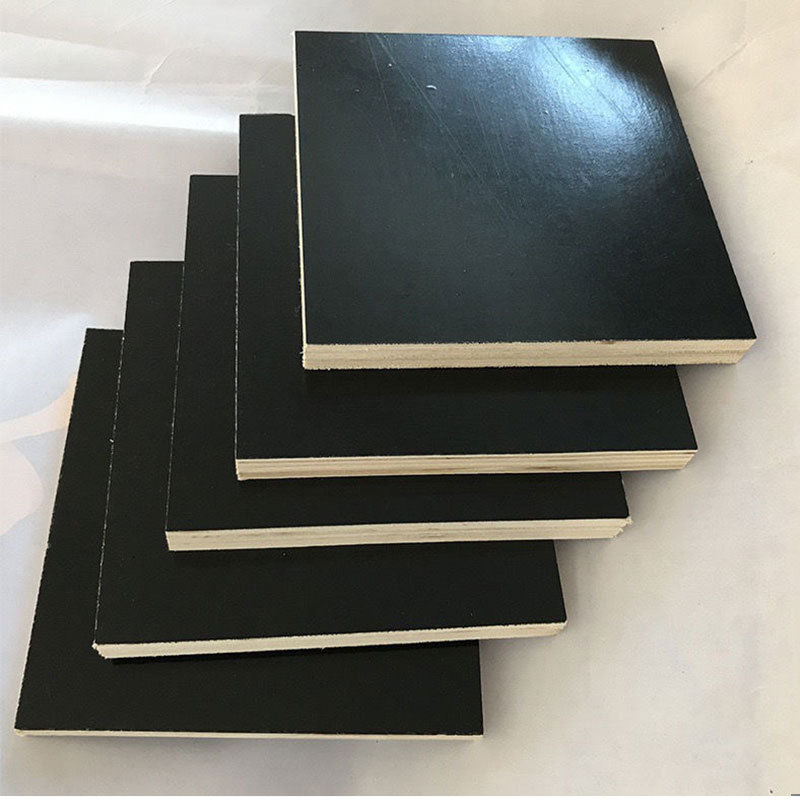

There are no gaps on the side to prevent rainwater from entering. It has good waterproof performance and the surface is not easy to wrinkle. Therefore, it is used more frequently than ordinary laminated panels. It can be used in areas with harsh weather and is not easy to crack and not deform.

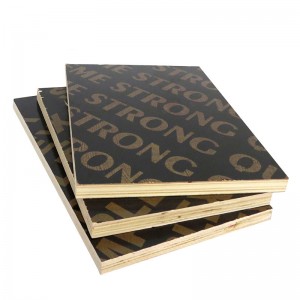

The black film faced laminates are mainly 1830mm*915mm and 1220mm*2440mm, which can be produced according to the thickness requirements of 8-11 layers of customers. The secondary hot press is used for flattening to ensure the uniformity of the plywood, good bonding strength and viscosity, and uniformity.

Features & Advantages

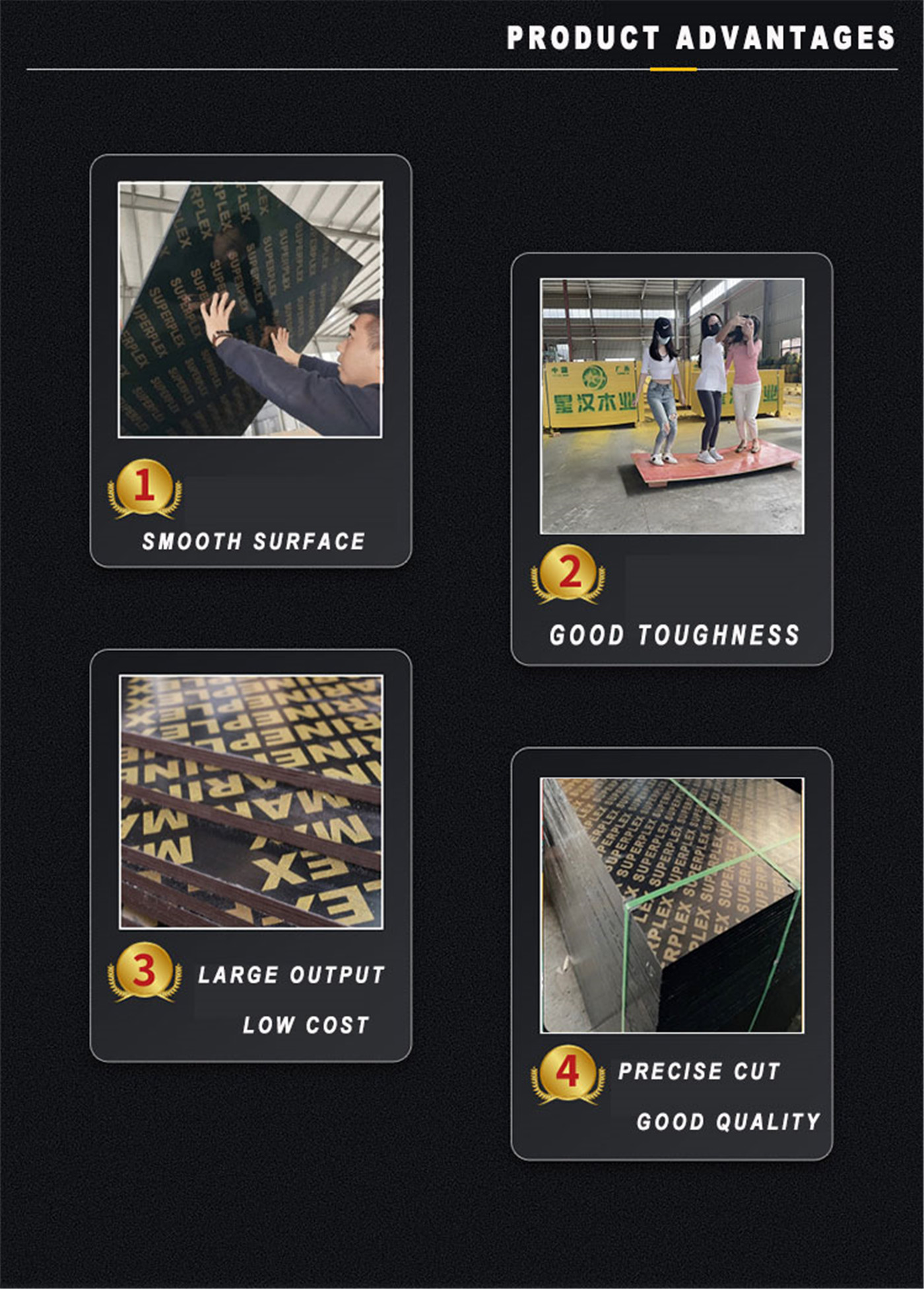

1.The surface of melamine faced concrete formwork plywood is easy to clean with water or steam,it helps to provide engineering construction efficiency.

2.Durable wear resistant, and is corrosion resistant to ordinary acid and alkali chemicals.It has the characteristics of anti-insect, high hardness and strong stability.

3.Has good freezing resistance and high temperature performance ,good toughness.Used in harsh environments, it still performs very excellent.

4. No shrinkage, no swelling, no cracking, no deformation under high temperature conditions, flameproof and fireproof,and can be used repeatedly for more than 10-15 times.

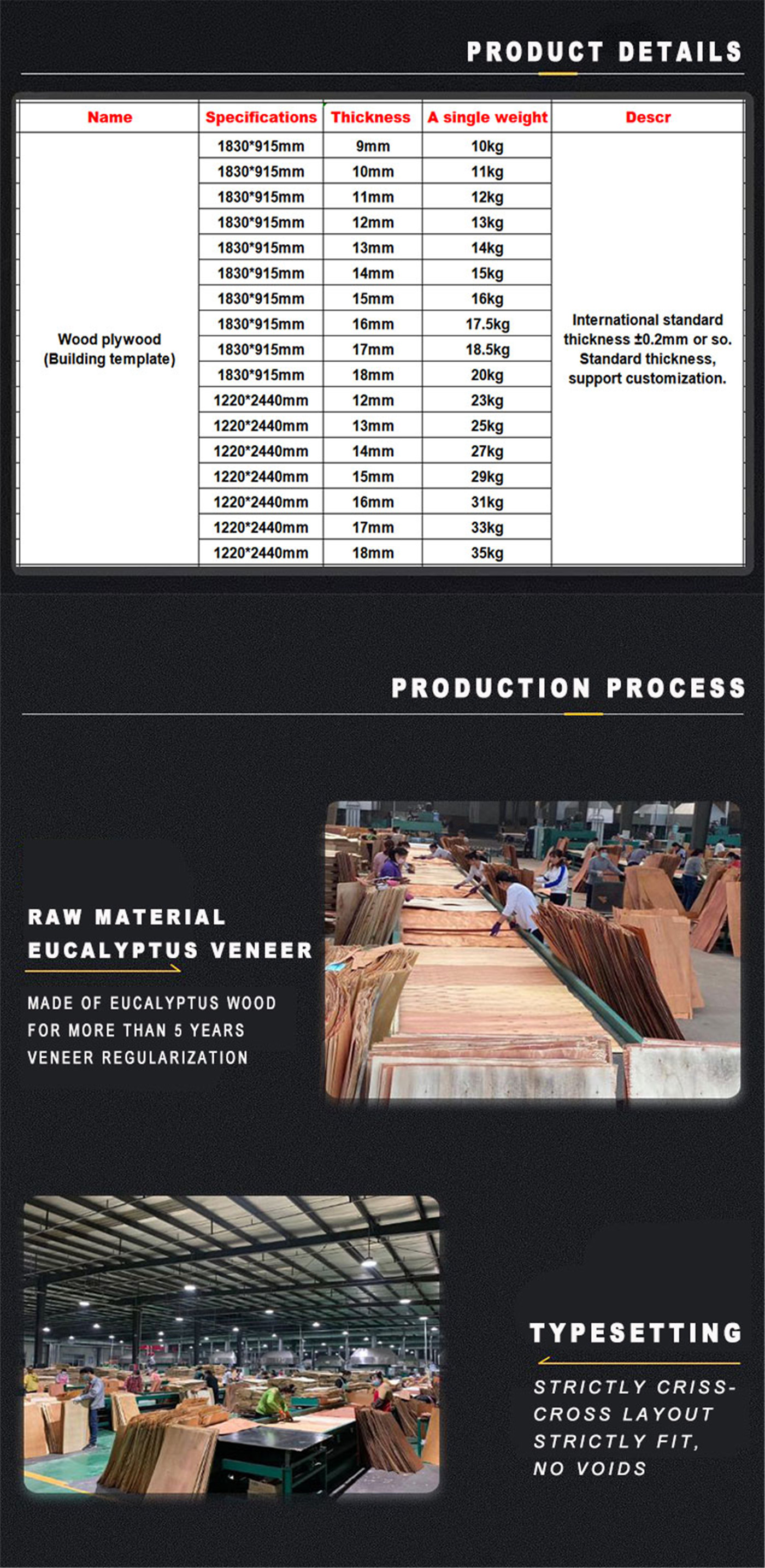

Parameter

| Place of Origin | Guangxi, China | Main Material | pine, eucalyptus |

| Brand Name | Xinhang | Core | pine, eucalyptus or requested by clients |

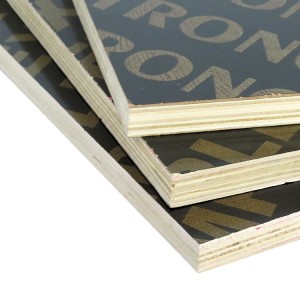

| Model Number | CONCRETE FORMWORK WOOD PLYWOOD | Face/Back | black(can print log) |

| Grade/Certificate | Glue | MR, melamine, WBP, phenolic | |

| Size | 1830*915mm/1220*2440mm | Moisture content | 5%-14% |

| Thickness | 11.5mm~21mm or as required | Density | 600-690 kg/cbm |

| Number of Plies | 8-11 layers | Packing | Standard export packing |

| Thickness Tolerance | +/-0.3mm | MOQ | 1*20GP. Less is acceptable |

| Usage | Outdoor, construction, bridge, etc. | Payment Terms | T/T, L/C |

| Delivery Time | Within 20 days after order confirmed |