-

18 Mm Red Phenolic Plywood Rate Online

The red construction film faced plywood (short for red board). The red board of our factory has been selected the first class panel material to rotate the veneer with the moderate thickness so as to meet the EU standards and customer needs. The dry and humidity of red board is strictly controlled by master craftsmen to ensure the bonding strength of the plywood. Our typesetting process is strict that to ensure our plywood has a moderate thickness, the core board relies on special tri-ammonia glue and its material is eucalyptus, the glue can reach more than 500g on each sheet.

-

Phenolic Red Film Faced Plywood For Construction

The panel is made of phenolic resin glue with strong waterproof performance, and the core plate is made of special tri-ammonia glue. The single-layer glue amount is more than 500g. Strict layout process management, so as to achieve criss-crossing, strict seam joints, and no voids.

-

18 Mm Veneer Pine Shutter Plywood

The red board plywood of the engineering has large size and flat surface. This feature can reduce the workload, and don’t need too many personnel to carry out the formwork, pouring,and demoulding construction operations. It can save a lot of labor costs.

The color of this construction plywood is bright,clean, smooth, and the color can be red ,black ,brown or as required.Besides, the logo can be printed according to requirements.

-

Film Faced Plywood Black Board

The standard size specifications of this plywood is divided into: 1220mm*2440mm and 1830mm*915mm, and the thickness is generally between 11-21mm.

The surface of this plywood is smooth and flat, and it is easy to demould during use, which makes the surface of the concrete smooth and convenient for workers to operate. Select high-quality pine wood and eucalyptus wood as raw materials, which have small lump and good toughness.

-

15mm Formwork Phenolic Brown Film Faced Plywood

The Super Smooth Film Faced Plywood has a smooth surface, is easy to demould, and has a good use effect. It is easy to clean with water or steam, which helps to improve the efficiency of engineering construction.

After 28 procedures, two times of pressing, five times of inspection and high-precision size can be packaged.

-

New Architectural Membrane Plywood

The secondary molding of film-coated plywood has good gloss, hardness, high strength, and smooth surface. Secondly, it has good water resistance and waterproof performance, so the formwork is not easy to be deformed and out of shape, with long service life and high turnover. It is the main product of Monster Wood , a construction plywood manufacturer. Once again, it has strong anti-corrosion performance, only a few strong acids and strong alkalis can damage it, and generally it can resist.

The color of the film faced plywood is bright,clean, smooth, and the appearance is black (red, brown or as required), and the logo can be printed according to requirements.

-

18mm Film Faced Plywood Film Faced Plywood Standard

18mm film faced plywood standard is the most common specification for import and export. 18mm film faced plywood has good durability, is not easy to deform, does not warp, and it can be reused up to 15-20 times, which is environmentally friendly and the price is affordable. Specifications are 4*8;4*7;3*7;4*6;3*6, other specifications can also be customized.

-

Plastic Pp Film Faced Plywood Shuttering For Construction

The plastic surface plywood is an innovative product(plastic surface construction plywood) that heats and presses the plastic surface layer on the wooden plywood. The sheet-shaped hot-melt plastic and the wooden plywood surface are pressed tightly by a calendar. Hot melt and press together.

-

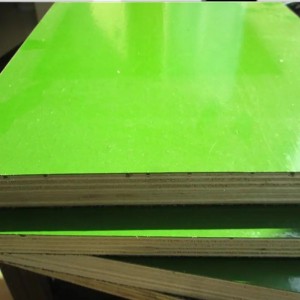

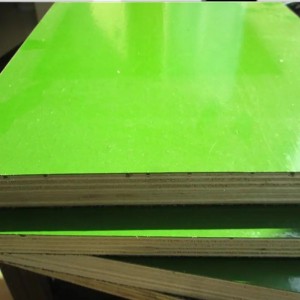

Water-Resistant Green Pp Plastic Film Faced Formwork Plywood

The durable green plastic faced laminated plywood is made of first-grade eucalyptus and pine boards. The surface is impregnated with a waterproof phenolic resin and then heated and pressed to form a wood construction plywood. The surface is smooth and flat,and the production plant has excellent technology. The plywood is not only sturdy and durable, but also easy to disassemble, which makes the building shape beautiful and has a wide range of applications. The number of cycles is up to 25 times. We provide customers with customized specifications and thickness.

-

Durable Green Plastic Faced Laminated Plywood

Our plastic faced plywood are of high quality, not easy to be deformed or warped, and recycled can be up to 30 times, which is economical and environmentally friendly.

The PP plastic coated plywood panel selects high-quality pine & eucalyptus as raw materials;High-quality glue/sufficient glue is used, and equipped with professionals to adjust the glue; A new type of plywood glue cooking machine is used to ensure uniform glue brushing and improve product quality.

-

High Quality Plastic Surface Environmental Protection Plywood

Construction plywood manufacturers are mainly concentrated in several provinces such as Guangxi, Jiangsu, Zhejiang and Shandong.

Introduce the use frequency of plywood: more than 25 times for plastic faced plywood,more than 12 times for film faced plywood, and more than 8 times for phenolic board. The use of construction plywood involves not only installation but also demolition. Plywood can be repeated multiple times if demolded correctly.

-

Green Plastic Faced Plywood/Pp Plastic Coated Plywood Panel

Water-resistant green PP Plastic film faced formwork plywood is a new type of environmentally friendly building material. It is another new generation product after wood formwork, steel formwork, bamboo and wood glued formwork, and all-steel big formwork. Its interior is made of wood and the surface is covered with plastic (PP Plastic). It is widely used in the pouring of concrete square columns, walls, and roofs. It is especially suitable for bridges, high-rises, tunnels and other projects. It combines the characteristics of the wooden formwork and the advantages of the plastic formwork, make it a good formwork for concrete pouring in key projects, which is environmentally friendly and has low amortized cost.